Installation

preparation:

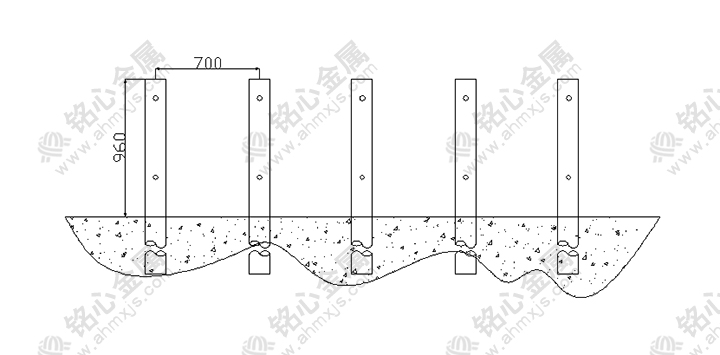

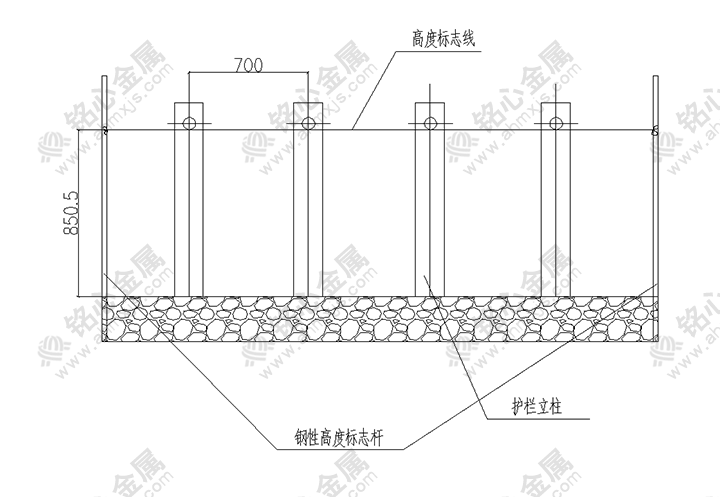

Of the guardrail road reserve position marked by lime powder line installation & have spent & have spent Lime line. And according to the interval of 700 mm mark the guardrail post installation position accurately。

The installation sequence:

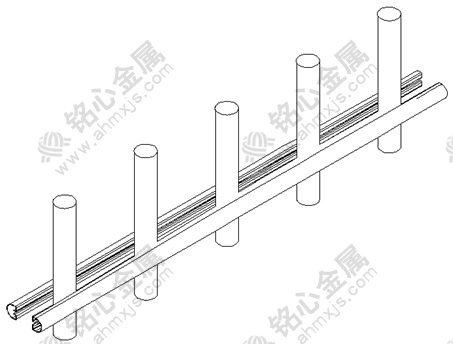

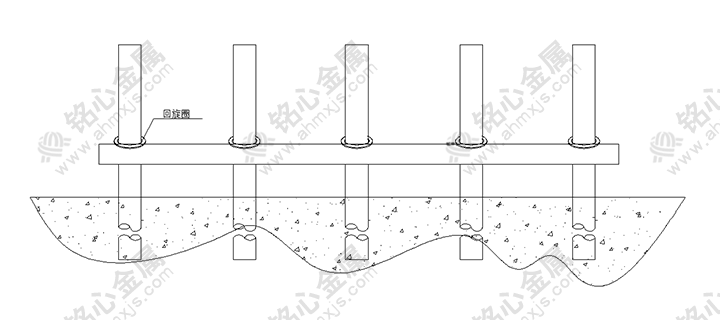

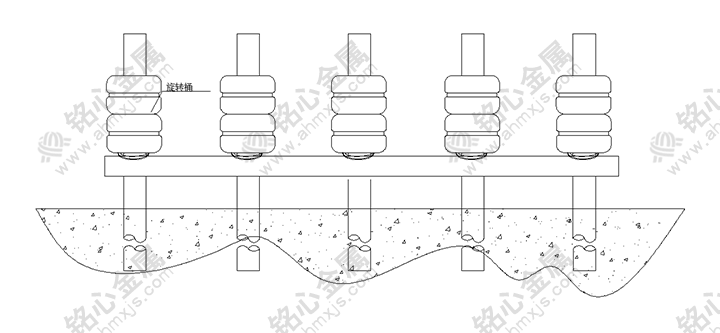

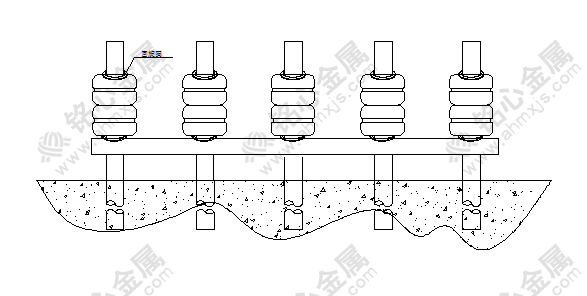

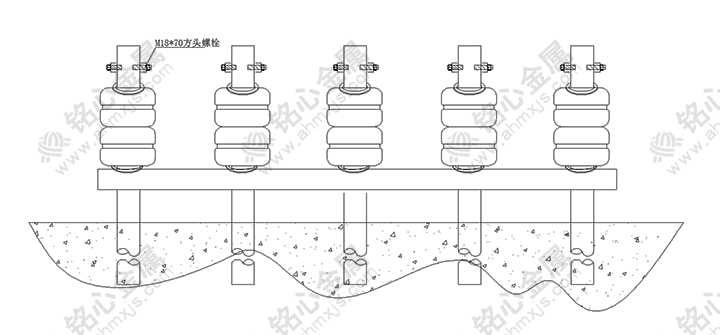

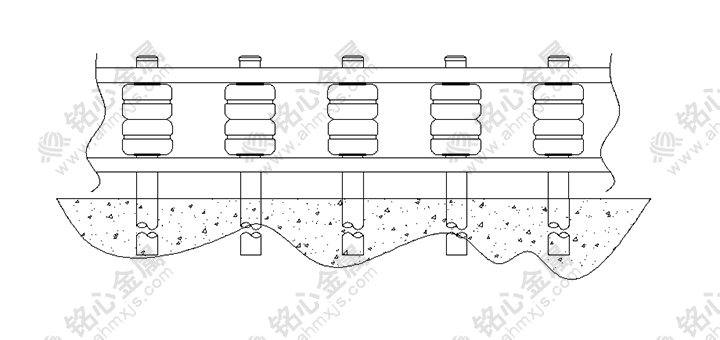

1.post 2.Lower beam 3.Cyclotron circle 4.Rolling cylinder 5.Cyclotron circle 6.Higher beam 7.Column head (see chart).

Under the column

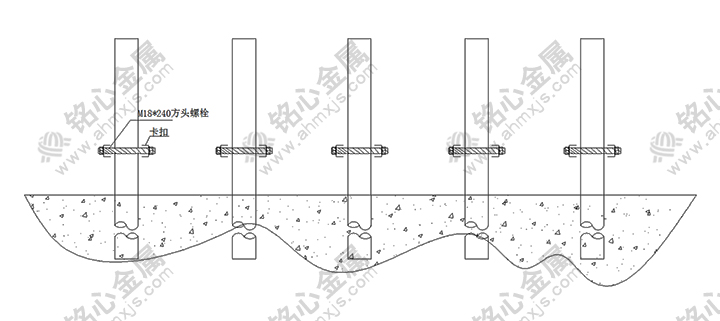

On M18 x 240 square head bolt and the buckle

On two beams under (leaks sink down)

Put a circle of cyclotron

Put the rotating barrel

Put a circle of cyclotron

On M18 x 70 square head bolt and the buckle

On the path of the two beams (leaks sink down), column cap shape

The installation:

Post installation:

Installation height:

The scheduled installation guardrail lime online vertical vertical two rigid pavement height mark pole, spacing of 10 to 20 meters. At the height of 850.5 mm horizontal stroke pulls a thin line (or with a laser height gauge on the highly illuminate a straight and level) 。

Install the pillar:

At a predetermined label position vertical laying the pipe。

Requirements :

(1)Column vertical surfaces, the angular deviation is less than 30’。

(2)The phi 19 mm at the top of the column of perforation and road axis vertical center axis. The hole along with the height (850.5 mm) needs to be flat. (column total height 1960 mm, height is 960 mm above the ground.) Figure 1 for the schematic。

Materials and accessories

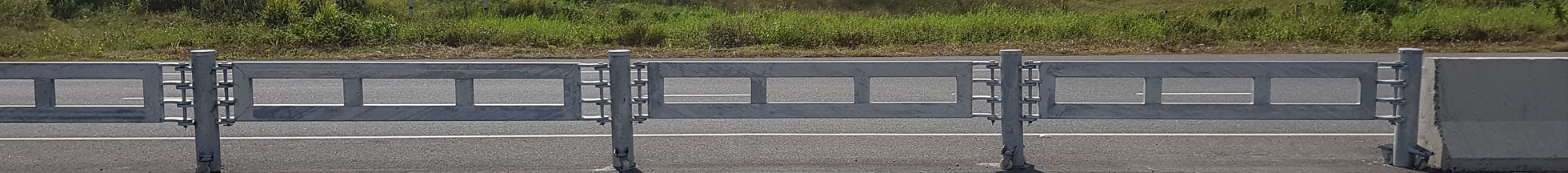

Guardrail by rotating barrel, column, beam, cyclotron, card buckle, casing, end and bolt (see table below)

Guardrail components composition and specifications and USES

|

Number |

Name |

Size |

Purpose |

Dosage |

Instructions |

|

1 |

Rotating barrel |

φ |

Absorb collision energy, to control vehicle guidance |

|

|

|

2 |

Stand column |

φ |

To absorb collision energy, supporting beam and rotating barrel |

|

|

|

3 |

The beam |

115×82×4.0 |

Absorb collision energy, connection column |

|

|

|

4 |

Cyclotron circle |

φ |

Facilitate the rotating barrel rotation |

|

|

|

5 |

Card buckle |

50×50×4.0 |

Connecting the beams and columns |

|

|

|

6 |

End socket |

700×120×4.0 |

To absorb collision energy, guardrail end connection |

|

|

|

7 |

Branch pipe |

105×70×4.0 |

Connection beam |

|

|

|

8 |

Bolt |

M18×70 Coach bolt |

Connected to the beam and column |

|

|

|

9 |

M18×240 Coach bolt |

The connection of beam and column |

|

|

|

|

10 |

M16×150 Coach bolt |

Connecting beams and the end |

|

|

Installation tools:

Ratchet wrench wrench: 30 mm (or open end wrench, or ring spanner)

Gas cutting equipment

Electric welding machine

Polishing machine

Nylon belt tightener

Wooden hammer