News

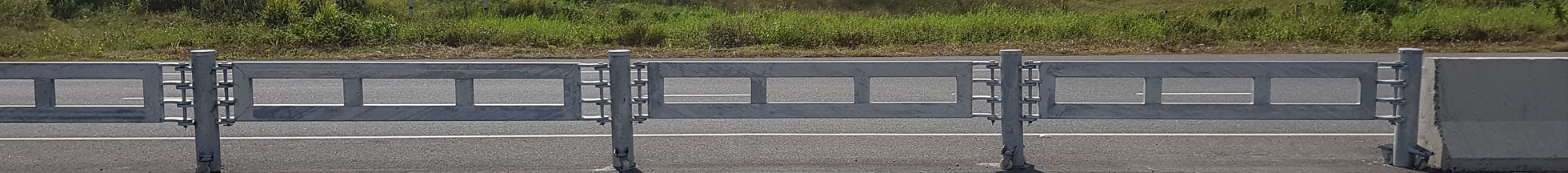

Keywords guardrail, rigid material surface treatment ( electrostatic spraying )

Date:2017-07-08 Views:466

We are no longer familiar with hot - dip galvanized Powder, because whether the wall at home or factory school walls, or balcony rails and assembly barriers, there are more opportunities to see more of the hot dip galvanized steel spray barrier, we will also see that the barrier can be used in many places, the hot - dip galvanized - sprayed guardrail is different from the small shop in the street, the market is generally painted or painted, and we are using electrostatic spray process, this spray is after high temperature curing the powder coating on the surface of a process method.

1, the static treatment of hot dip galvanized guardrail can better protect the product, not only enhance the durability and trial of the appearance, the product itself is also more beautiful and beautiful. Now, electrostatic spraying technology has become an indispensable process operation, especially the appearance of some instruments, the beautiful shape will always be a customer purchase of a favorite reference choice, if carefully observed, the home electrical shell is almost our electrostatic spray process.

2, the static electricity treatment of hot - dip galvanized steel spray barrier is conducive to the long-term use of the guardrail, reduce maintenance and repair work. Moreover, because of the particularity of this kind of barrier, only through static can the powder can be adsorbed on the raw material of the guardrail, after all, powder is not liquid, not paint, can not be manually operated, based on the principle and practical advantages, the value of electrostatic spray technology is much higher than painting.

3, electrostatic treatment is conducive to environmental protection. This technology is very suitable for now people's life, can play an environmental role. We know that now with the change of the air environment, there are many places under the rain or snow will be a bit corrosive, there are many common spray technology like paint paint, there is no way to resist the natural wind of these external factors of the sun, play anti - corrosion, anti - acid. The use of electrostatic spray technology will play a good protective role on the product itself.

1, the static treatment of hot dip galvanized guardrail can better protect the product, not only enhance the durability and trial of the appearance, the product itself is also more beautiful and beautiful. Now, electrostatic spraying technology has become an indispensable process operation, especially the appearance of some instruments, the beautiful shape will always be a customer purchase of a favorite reference choice, if carefully observed, the home electrical shell is almost our electrostatic spray process.

2, the static electricity treatment of hot - dip galvanized steel spray barrier is conducive to the long-term use of the guardrail, reduce maintenance and repair work. Moreover, because of the particularity of this kind of barrier, only through static can the powder can be adsorbed on the raw material of the guardrail, after all, powder is not liquid, not paint, can not be manually operated, based on the principle and practical advantages, the value of electrostatic spray technology is much higher than painting.

3, electrostatic treatment is conducive to environmental protection. This technology is very suitable for now people's life, can play an environmental role. We know that now with the change of the air environment, there are many places under the rain or snow will be a bit corrosive, there are many common spray technology like paint paint, there is no way to resist the natural wind of these external factors of the sun, play anti - corrosion, anti - acid. The use of electrostatic spray technology will play a good protective role on the product itself.